We are happy to annouce, that Aareplast achieved the ISO 14001:2015 Certificaton.

We are happy to annouce, that Aareplast achieved the ISO 14001:2015 Certificaton.

We are happy to confirm that we can still assure the availability for our client's orders.

We are happy to confirm that we can still assure the availability for our client's orders.

Aareplast at Hannover Messe 2019

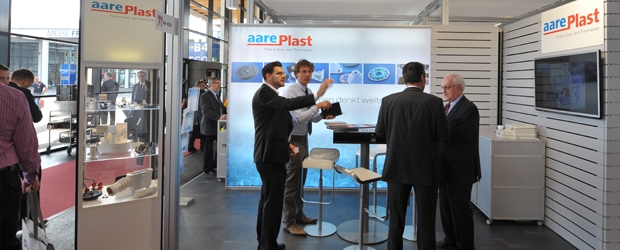

Aareplast at Fakuma 2017

Aareplast becomes a member of the SWISSRAIL Industry Association

We are pleased about the admission into the SWISSRAIL Industry Association which improves the cooperation within the sector and strengthens our network in the field of railway technology. (5/2015)

Increasing efficiency: Aareplast invests in state-of-the-art deburring machines for thermoset manufacturing

Due to the manufacturing process, thermosets cannot be produced free of burrs. Using our state-of the-art deburring machines, the burr is mechanically removed from the plastic components. Shot blasting is a highly proven surface technology and – along with the use of 6-axis robots – displays a further step towards increasing efficiency in our production processes. (4/2015)

Our investments: Fully-automated thermoset production saves time and cuts costs

Our fully-automated thermoset production technology ensures that you benefit from fast and efficient production which guarantees consistently high quality standards at attractive prices.

Aareplast AG is now ranked in first place for the production of Swiss service entrance boxes. In the case of fully-automated production of thermoset semi-finished products, it is no longer necessary to manually load the metallic parts or to carry out manual reprocessing work. During thermoset injection moulding, the manufacturing process and reprocessing work are carried out entirely automatically. The plastic component is transported to the reprocessing station following demoulding, where sprue and overflows are removed automatically.

Aareplast AG at Fakuma 2014

From 16 to 20 October 2014, experts from the world of plastics processing came together once more at FAKUMA, held in Friedrichshafen. Our visitors showed a great deal of interest in thermoset processing in particular. The trade fair was definitely a success and we are already looking forward to the next FAKUMA.

Aareplast AG increases its production capacity due to growing demand

In order to meet the demands of our customers, we have expanded production in the field of thermosets and thermoplastics. For example: In a fully automated manufacturing cell, metal contacts are inserted into an injection moulding tool and overmoulded with thermoset. (4/2013)

Growing management

Martin R. Wipf has been a member of the management team at Aareplast AG since the beginning of August 2012. "As the company owner's son, we have already settled the question of company succession, and I believe the firm has great potential; which we definitely hope to capitalise on in the near future." Martin R. Wipf

A business development delegation from the Swiss Canton Solothurn visits Aareplast AG

A healthy economy needs SMEs which display innovative strength. For this reason, a business development delegation from the Swiss canton of Solothurn visited Aareplast AG.

The delegation, led by Esther Gassler (Government Councillor and Economic Director of Solothurn), was highly impressed by the technology used in both thermoset and thermoplastic processes presented. The production of both service entrance boxes and plastic surface boxes (substitution) were among the key topics of the visiting day.

Present at the Aareplast AG visiting day were:

Esther Gassler, Government Councillor and Economic Director of the Canton of Solothurn

Ernst Zingg, Mayor of Olten

Jonas Motschi, Head of the Cantonal Office for Economics in Solothurn

Karin Heimann, Head of Business Development in the canton of Solothurn

Dieter Leu, local Mayor of Rickenbach

Urs Blaser, Business Development in Olten

Dr. Ernesto Engel, Managing Director of the Swiss Plastics Association (KVS)

Aareplast AG at SWISSPLASTICS

From 17 to 19 January 2012, experts from the world of plastics gathered together in Lucerne to attend the SWISSPLASTICS trade fair. The Aareplast trade fair stand proved to be an ideal meeting point for clients and prospective buyers in the area of thermoset and thermoplastic solutions. The trade fair was definitely a success and we are already looking forward to the next FAKUMA.

Aareplast AG and Schulman AG at the Fakuma 2011

From October 18 until October 22, 2011, the plastics professionals once again met at the FAKUMA trade fair which was staged at the Messe Friedrichshafen. As the partner company of Schulman AG, Aareplast AG was present at the trade fair booth with its plastic access covers for water and gas lines. Aareplast AG’s access cover application with Schulamid 612 GF 50 – a success story in the field of metal substitution – sparked a great deal of interest among the trade fair visitors.

Mrs. Tomann of A. Schulman, Marketing Communication Europe,

with Robert Wipf, CEO Aareplast AG Switzerland